Tim Oliver

KOKO Trust

RD2 CAMBRIDGE

14 Feb. 01

Glen Atkinson

BDMax Biodynamics

83 Town Point Rd RD9

TE PUKE

Dear Glen

I thought it about time that I give you a written update on our experiences with PVH (Passion Vine Hopper) and peppering.

In 1988/89 (our first experience with PVH) we lost 40-50% of the fruit in block 3 behind the house (1.3 ca ha). Graham Cathie and other packhouse staff had never previously seen sooty mould like it. We then used ‘Attack’ until converting to Kiwigreen and organics in 1992-93. Low levels of PVH have been established throughout the orchard (which is now producing on 10.5 ca ha) with viable eggs on structures and fruit stalks.

The past three or four summers have been bad to very bad for PVH pressure, based on observation in our garden and orchard surrounds, in Cambridge and from comments by the Ruakura entomologists. This summer there were nymphs on the indicator jasmine in October, but development appeared to be slower, possibly due to the cooler spring temperatures. However, with the sun in December they have kicked along pretty successfully and have been solid (50-100 per stem) on the black walnut seedlings on the edge of the bank behind the shed.

So far we have observed only a very few PVH in the kiwifruit vines and an occasional fruit with honeydew or sooty mould. Certainly more will darken before harvest, but there’s nothing to panic about. We think it will be a bit like the minimal levels of sclerotinia found following the conditions at New Year that were perfect for serious fungal infection;

Certainly, the first two years we used the pepper you made from our own PVH, there was a dramatic improvement within the orchard test. 70-80% reduction in fruit loss but we still had a couple of hot spots in blocks 1 and 3. These were not thinned for sooty mould in 2000 and eventually accounted for about 1600 trays or 1.7% of the total harvest. We accept that there were some inadequacies with the spray programme for PVH over these years.

Interestingly, in 1998-99 Cheryl Thompson (who is a member of Dr Andrew Tompkins entomology team at Ruakura) was quite astonished at the lack of PVH in the block where she was doing the Encarsia release trial.

Unfortunately, we had no sprayer this spring so no seaweed, E(therics)1000 or PVH (pepper) was applied until the first post-blossom spray in December. However, I have added PVH (pepper) to each of the four oil and/or Bt sprays since then, with 501 being included twice. The timing of these sprays, which usually take 2-4 days to apply to the whole orchard, has been controlled mainly by the weather, so very few areas will have been sprayed at the biodynamically optimum times. I have not sprayed over the banks at all but, depending on wind strength and direction, I have sprayed some of the headlands and into the shelter.

The total cost of this preventative measure has been the PVH pepper at about $l0-12/ha/spray. (I use 250 mi/ha and increase towards 300 mi/ha in the historical problem areas.)

My impressions at mid-february 2001 are that this is the most encouraging year so far. We have not been able to find enough PVH on the vines to warrant sucking them off or squashing them by hand.

The vines are now managed with a more open canopy and should have strengthened internally after 8 seasons under our organic regime and with the two recent 501 sprays. Therefore, they may not be as attractive to PVH as they were 10 years ago. However, we estimate that, without concerted effort (e.g. mechanical or broad spectrum spray) our minimum annual losses from sooty mould would be 5-10,000 trays and possibly as high as 20-25,000 based on past experience.

We firmly believe that the primary factor in preventing these losses has been the application of the PVH pepper. Peppering has worked, with the other organic positives on our property, to achieve this huge improvement at a cost of less than $50/ha/year. There is never an application cost because it is always added in with other sprays. As with so many organic/BD techniques this is not the level of $ that inspires chemical companies and conventionally funded scientists!

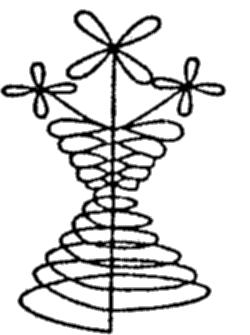

Glen, I realise that this is all just anecdotal and that it is very difficult to set up as a trial, because of the areas and years involved. We will continue to use the pepper, and possibly make a new batch in a year or two, because we know that it has saved us well over $100,000 in the past five or six years. All from one cup of PVH and your potentising of the ash residue through dilution.

I hope you find this interesting and useful for your experiential records. Kind regards,

Tim Oliver (signed)